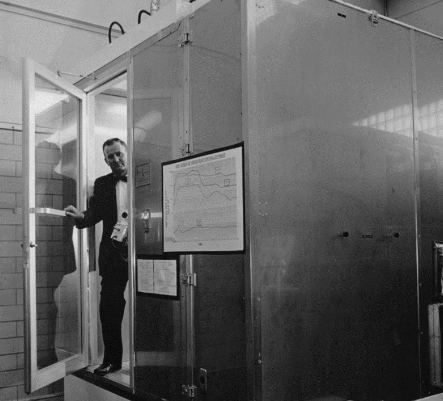

Clean rooms play a vital role in industries where precision and contamination control are paramount. These highly controlled environments are used in sectors such as semiconductor manufacturing, pharmaceuticals, biotechnology, and aerospace to ensure product quality, research accuracy, and safety. However, even in the most meticulously designed clean rooms, the risk of user errors remains a significant concern. In this blog post, we will explore the common user errors in clean rooms and discuss strategies for mitigating them.

The Importance of Clean Rooms

Clean rooms are classified based on the number of airborne particles allowed per cubic meter of air, with Class 1 being the strictest and Class 9 the least. The stringent requirements for cleanliness in clean rooms are crucial because even the tiniest contaminants can have a detrimental impact on product quality, research outcomes, or patient safety. User errors in these environments can lead to costly mistakes and, in some cases, safety risks.

Common User Errors in Clean Rooms

- Gowning and Personal Hygiene Errors: Clean room personnel must follow rigorous gowning procedures and observe proper personal hygiene to prevent contamination. Common errors include improperly donning cleanroom garments, failing to secure gloves, or neglecting to wash hands and face before entry.

- Inadequate Training: Users who are not adequately trained in clean room protocols and procedures may unintentionally introduce contaminants or mishandle sensitive equipment.

- Protocol Deviations: Deviating from established clean room protocols and procedures can lead to contamination or safety risks. This may happen intentionally or accidentally.

- Improper Equipment Handling: Mishandling of cleanroom equipment or tools can introduce contaminants or damage sensitive instruments. Users should be trained in the correct handling and use of such equipment.

- Cross-Contamination: Mixing materials, chemicals, or equipment from different areas within the clean room can lead to cross-contamination. Maintaining separation is crucial.

- Failure to Report Issues: Prompt reporting of anomalies or issues within the clean room is essential. Failing to do so can lead to delayed response and problem resolution.

- Lack of Properly Documenting Activities: Users manually take note of data and this data is then input electronically into a software by another user. Human error is common by missing crucial data or misinterpreting hand-writing.

Strategies for Mitigating User Errors

- Comprehensive Training: Ensure all clean room personnel receive thorough training in clean room protocols, gowning procedures, and personal hygiene requirements.

- Strict Adherence to Protocols: Emphasize the importance of adhering to established clean room procedures and protocols. Deviations should be avoided whenever possible.

- Clear Documentation: Maintain accurate records of processes, equipment usage, and environmental conditions. This documentation aids in identifying potential sources of contamination and tracking adherence to protocols.

- Routine Inspections and Maintenance: Conduct regular audits and inspections to identify and address equipment malfunctions, filter inefficiencies, and other infrastructure issues that could compromise cleanliness.

- Waste Disposal Procedures: Ensure that waste disposal is handled correctly and that users are well-informed about designated waste disposal methods and containers.

- Monitoring and Reporting Culture: Foster a culture of vigilance and responsibility where users are encouraged to report issues and anomalies promptly.

- Minimizing Distractions: Encourage users to minimize unnecessary movements and distractions in the clean room. Fidgeting with equipment or touching surfaces should be avoided.

Consensus

User errors in clean rooms can have far-reaching consequences, from compromising product quality to putting research at risk. To mitigate these errors, organizations and clean room facilities should prioritize training, adherence to protocols, and a culture of cleanliness and precision. Regular audits and inspections are essential to identify and address issues promptly, ensuring that the clean room maintains its integrity and serves its critical role in maintaining high standards of quality and safety in various industries.