The biotech industry is at the forefront of scientific innovation, developing products and solutions that often directly impact human health and the environment. A critical factor in maintaining the integrity of this industry’s outputs is the strict adherence to a sanitary routine. This routine is essential to prevent contamination and ensure the safety and efficacy of biotech products. Below are key components of the sanitary routine within the biotechnology industry and why they are indispensable.

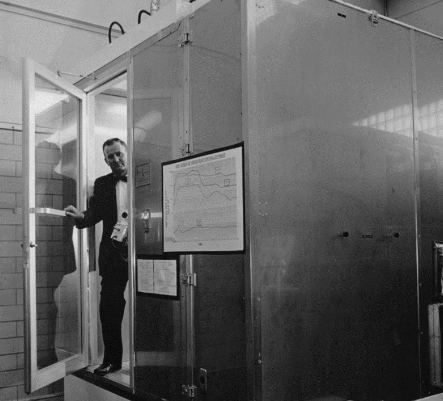

Understanding Cleanrooms and Clean Spaces

In the biotech industry, cleanrooms and clean spaces are pivotal in maintaining a controlled environment where products can be developed and manufactured without the risk of contamination. Cleanrooms are designed to maintain an exceedingly low level of airborne particles, such as dust, aerosol particles, and chemical vapors. They achieve this through the use of HEPA (High-Efficiency Particulate Air) filters, which trap particles that are 0.3 microns and larger in size, and through rigorous control of environmental parameters including temperature, humidity, and pressure.

Industry Standards for Cleanrooms

The industry standards for cleanrooms are defined by the number of particles allowed per cubic meter, at a specified particle size. The International Standards Organization (ISO) classifies cleanrooms from ISO 1, the cleanest, to ISO 9, based on the allowable particle count. For example, an ISO 5 cleanroom allows 100,000 particles per cubic meter of 0.1 microns or larger, and is comparable to a Class 100 cleanroom in the older standard.

The Importance of a Sanitary Routine

Maintaining a sanitary routine is vital for biotech companies to meet the stringent industry standards. This routine includes several practices:

Regular Cleaning and Disinfection

Surfaces within cleanrooms and clean spaces must be regularly cleaned and disinfected with appropriate solutions that eliminate potential contaminants without damaging the sensitive environment. This involves wiping down work surfaces, equipment, and even walls and floors with sterilized wipes and mops.

Personnel Hygiene and Garbing Procedures

Individuals working in cleanrooms must adhere to strict garbing procedures, which include wearing specialized clothing such as gowns, hoods, masks, and gloves that are designed to prevent the shedding of skin, hair, and fibers. Personnel must also follow stringent hygiene protocols, such as hand washing and using non-shedding materials.

Equipment and Material Sterilization

All equipment and materials entering a cleanroom must be sterilized to prevent any external contamination. This often involves autoclaving or the use of chemical sterilants.

Adherence to Protocols

The effectiveness of a sanitary routine hinges on strict adherence to established protocols and procedures. Regular training and monitoring are essential to ensure that all personnel are up-to-date with the latest standards and practices.

Continuous Monitoring and Validation

Continuous monitoring of the cleanroom environment is crucial to detect any deviation from the required standards. This includes regular testing of air quality, surface contamination, and the integrity of HEPA filters. Validation activities confirm that the cleanrooms and equipment are functioning correctly and are effectively maintaining the required cleanliness levels.

The sanitary routine in the biotech industry is not just about maintaining cleanliness; it is about safeguarding the production process and ensuring the reliability of the biotech products. Adherence to these routines and standards is what allows the biotech industry to operate at the cutting-edge of science and technology, with the confidence that their products are safe for consumers and the environment.