Compliance with the Current Good Manufacturing Practices (CGMP) for the manufacture, processing, packing, or holding of products is essential for any organization that wants to maintain quality and safety standards. Among these guidelines is CAPPA, or Corrective Action and Preventive Action, a crucial component of the CGMP regulations. CAPPA compliance ensures that your organization can identify, address, and prevent issues that may compromise product quality or safety. This article will walk you through the importance of CAPPA compliance, key regulatory changes, and a compliance checklist to maintain clean rooms and other controlled environments in compliance with CAPPA.

Understanding CAPPA Compliance

CAPPA compliance is about taking a systematic and proactive approach to identify potential risks and errors in the manufacturing process and implementing corrective and preventive measures. The aim is to ensure that the processes are controlled, and products are consistently produced and controlled according to quality standards.

The Role of CAPPA in Quality Management

CAPPA is not just about meeting regulatory requirements; it’s an integral part of a robust quality management system (QMS). It helps organizations to:

- Detect and correct nonconformities before they impact product quality or customer satisfaction.

- Implement preventive measures to mitigate the risk of future nonconformities.

- Ensure continuous improvement in processes and quality standards.

Regulatory Changes and Impact

Regulatory bodies worldwide, including the FDA in the United States, are constantly updating their guidelines to ensure that they reflect the latest in scientific and technological advancements. Staying on top of these regulatory changes is critical for maintaining CAPPA compliance.

The CAPPA Compliance Checklist

To help your organization stay compliant with CAPPA, here’s a compliance checklist that covers the essential aspects of the CAPPA process:

1. Documenting the Process

Ensure that there is proper documentation for the CAPPA process. This documentation should detail how your organization identifies, assesses, and manages corrective and preventive actions.

2. Identifying Issues

Have a system in place for identifying quality issues that may require corrective or preventive action. This can include customer complaints, internal audits, or process monitoring.

3. Investigating the Root Cause

Once issues are identified, it is crucial to conduct a thorough root cause analysis to understand why the nonconformity occurred.

4. Planning and Implementing CAPPA Measures

Develop a plan for corrective and preventive actions and ensure that these measures are implemented effectively.

5. Monitoring and Reviewing

Regularly monitor the effectiveness of the CAPPA measures and review them to ensure they are working as intended.

6. Maintaining Records

Maintain records of all CAPPA activities, including identification, planning, implementation, and monitoring.

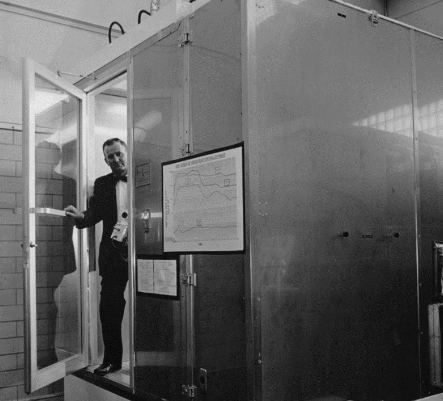

Maintaining Clean Rooms for CAPPA Compliance

Clean rooms and other controlled environments are critical in ensuring the quality and safety of products, especially in industries like pharmaceuticals and biotechnology.

Importance of Clean Rooms in Compliance

Clean rooms help prevent contamination and ensure that products are manufactured in a controlled environment. Maintaining clean rooms is thus an essential part of CAPPA compliance.

Regular Monitoring and Maintenance

Regular monitoring and maintenance of clean rooms are necessary to ensure that they meet the required standards. This includes checking air quality, temperature, humidity, and cleanliness.

Training Personnel

Personnel working in clean rooms should be adequately trained in proper procedures to maintain the environment and prevent contamination.

Updating Procedures with Regulatory Changes

As regulations change, procedures for maintaining clean rooms must be updated to ensure ongoing compliance.

Implementing Technology for CAPPA Compliance

Technology can play a significant role in ensuring CAPPA compliance. By leveraging the right tools, organizations can improve their ability to monitor processes, maintain documentation, and stay up-to-date with regulatory changes.

Compliance Software

Compliance software can help manage the documentation, workflows, and reporting necessary for CAPPA compliance.

Data Analytics

Data analytics tools can identify trends and patterns that may indicate areas of risk, helping to inform preventive measures.

Automation

Automation can reduce the potential for human error in processes and improve overall efficiency.

Challenges in Achieving CAPPA Compliance

Despite the importance of CAPPA, organizations often face challenges in achieving and maintaining compliance. These may include:

1. Lack of Resources

Some organizations may struggle with allocating the necessary resources, including time, personnel, and finances, to the CAPPA process.

2. Resistance to Change

Implementing CAPPA measures often requires changes to established procedures, which can meet with resistance from staff.

3. Complexity of Regulatory Requirements

The complexity and ever-changing nature of regulatory requirements can make it difficult for organizations to keep up.

4. Inadequate Training

Without adequate training, staff may not effectively implement or adhere to CAPPA procedures.

Best Practices for Ensuring CAPPA Compliance

Here are some best practices that can help organizations ensure CAPPA compliance:

1. Establish a Culture of Quality

Foster a company culture that prioritizes quality and compliance at all levels of the organization.

2. Engage in Continuous Training

Provide continuous training and education for staff on CAPPA procedures and the importance of compliance.

3. Invest in Technology

Invest in technology that can streamline the CAPPA process and improve accuracy and efficiency. We do help!

4. Stay Informed on Regulatory Changes

Keep abreast of regulatory changes and update CAPPA procedures accordingly to maintain compliance.

Conclusion

CAPPA compliance is an ongoing process that requires commitment, resources, and vigilance. By understanding the requirements, maintaining controlled environments like clean rooms, leveraging technology, and addressing challenges head-on, organizations can ensure that they remain compliant with CAPPA regulations. Remember, compliance isn’t just about avoiding penalties; it’s about ensuring the quality and safety of your products, which ultimately protects your customers and your brand’s reputation.