In the world of biotech and pharmaceuticals, clean rooms play a pivotal role. They are the unsung heroes, ensuring product safety and quality.

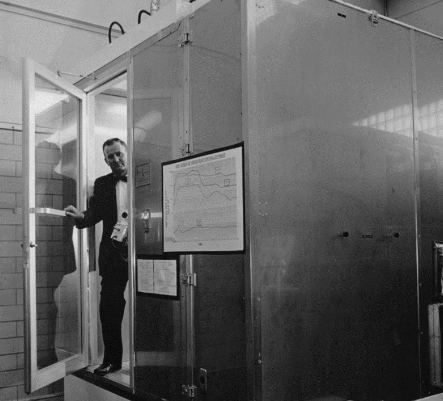

So, what exactly is a clean room? They are controlled environments, very carefully designed to limit pollution from particulates.

Various industries rely on these clean spaces. From electronics manufacturing to scientific research, clean rooms are essential.

In this article, we delve into the science behind clean spaces. We explore their importance across industries, and how they contribute to maintaining high standards of quality and safety.

What Are Clean Rooms?

Clean rooms are specialized facilities. They are designed to maintain extremely low levels of particulates, such as dust, airborne organisms, or vaporized particles.

These rooms are equipped with air filters, often High Efficiency Particulate Air (HEPA) or Ultra Low Penetration Air (ULPA) filters. These filters help to control the concentration of airborne particles.

The level of cleanliness in a clean room is dictated by the number of particles allowed per volume of air. This is often measured in accordance with ISO standards.

Clean rooms are used to keep sensitive processes safe from pollution or dirt by controlling the environment.

The Role of Clean Rooms in Industry

Clean rooms play a crucial role in various industries. They are particularly vital in sectors where contamination can have severe consequences.

These sectors include biotech, pharmaceuticals, and electronics manufacturing. In these industries, even minute contamination can compromise product quality and safety.

Clean rooms ensure that sensitive processes are carried out in a controlled environment. This minimizes the risk of contamination, ensuring product integrity.

Clean Rooms in Bio-tech and Pharmaceuticals

In the biotech and pharmaceutical industries, clean rooms play an absolutely vital role. They are an essential component in various stages of research, development, and

production processes. Clean rooms are specifically designed to maintain the utmost sterility of pharmaceutical products. This is of utmost importance, particularly in the

case of injectable drugs, where even the slightest contamination can have severe health consequences. In the field of biotechnology, clean rooms serve as a controlled

environment that enables the precise manipulation of delicate biological materials. By preventing cross-contamination, clean rooms ensure the accuracy and reliability of

research outcomes, as well as the overall safety and efficacy of biotech products. The meticulous maintenance of clean rooms is crucial to upholding the highest

standards of quality, safety, and regulatory compliance in these industries. It is a testament to the unwavering commitment of biotech and pharmaceutical companies to

deliver products that meet the most stringent requirements and safeguard the well-being of patients and consumers alike.

Learn more about Biotech Clean Rooms.

Clean Rooms in Electronics and Other Sectors

Clean rooms play a crucial role not only in the electronics industry but also in various other sectors. In the realm of electronics, clean rooms are indispensable for the

production of microchips, miniature computers, and electronic devices. The significance of clean rooms lies in their ability to ward off defects caused by even the tiniest

dust particles. By maintaining a pristine environment, clean rooms ensure the reliability and performance of electronic components. However, the electronics industry is

not the only beneficiary of clean rooms. Other sectors, such as aerospace and optics, also heavily rely on these controlled environments. In aerospace, clean rooms are

instrumental in preserving the precision and quality of products, especially when it comes to manufacturing sensitive components like satellites and aircraft parts.

Similarly, in the optics industry, clean rooms are essential for the production of high-quality lenses and optical devices, where even the slightest impurity can compromise

the final product’s performance.

Key Features of Clean Rooms

Clean rooms are characterized by their unique features. These features are designed to control the level of environmental pollutants.

One key feature is the air filtration system. This system removes particulate matter from the air, maintaining a clean environment.

Another feature is the use of specialized materials. These materials are chosen for their ability to resist particle generation and gathering of things.

Air Filtration and Laminar Flow

Air filtration is a critical aspect of clean rooms. High-efficiency particulate air (HEPA) filters are commonly used to remove particles.

The concept of laminar flow is also essential. Laminar flow guarantees that the filtered air moves one-way, lowering the likelihood of settled particles getting re-dispersed.

The combination of air filtration and laminar flow creates an environment with minimal particulate contamination.

Clean Room Classifications and Standards

Clean rooms are classified based on their cleanliness level. This is determined by the number and size of particles allowed per volume of air.

The International Organization for Standardization (ISO) provides a standard for clean room classification. This standard, known as ISO 14644-1, defines nine classes of clean rooms.

Each class corresponds to a specific level of cleanliness. The class required depends on the sensitivity of the processes being carried out.

The Impact of Clean Rooms on Safety and Quality

Clean rooms play a crucial role in ensuring safety and quality. They provide a controlled environment for sensitive processes.

In industries like biotech and pharmaceuticals, clean rooms prevent product contamination. This is vital for patient safety and efficacy of medicines.

In electronics manufacturing, clean rooms help achieve precision. They prevent defects that can compromise the performance of microchips and semiconductors.

Overall, clean rooms contribute significantly to product reliability and consumer trust.