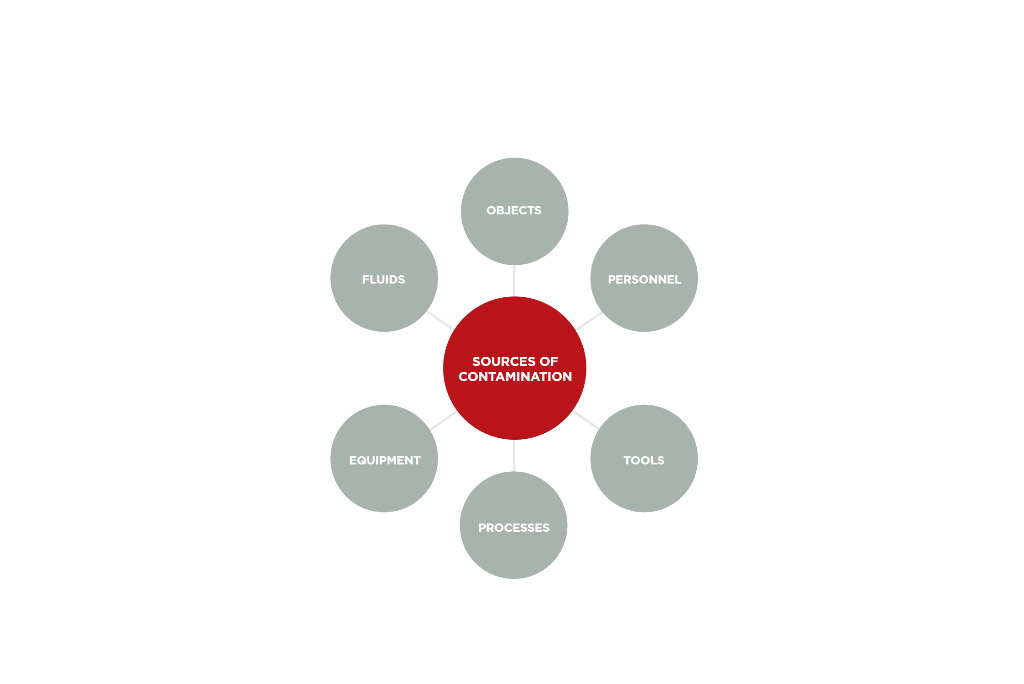

The prevention of contamination from entering or leaving the controlled environment is essential to ensure the quality, reliability, and safety of the products, processes, or experiments. In this blog, we will explore how clean rooms prevent contamination from entering or leaving the controlled environment and what steps are taken to minimize risks.

Preventing Contamination from Entering the Controlled Environment

One of the primary goals of clean room contamination control is to prevent it before it starts. There are several strategies used to achieve this goal.

- Air Filtration Systems: Clean rooms use specialized air filtration systems to remove particles from the air. HEPA (High-Efficiency Particulate Air) filters are commonly used in clean rooms to remove particles as small as 0.3 microns from the air.

- Controlled Air Flow: Clean rooms use controlled air flow to prevent the introduction of contaminants from outside the controlled environment. The air pressure in the clean room is maintained at a higher level than the surrounding areas, creating a positive pressure differential that prevents the entry of contaminants.

- Gowning Procedures: Clean room personnel are required to follow strict gowning procedures to prevent the introduction of contaminants. Clean room garments, such as coveralls, hoods, gloves, and masks, are worn to prevent particles from the skin, hair, and clothing from contaminating the environment.

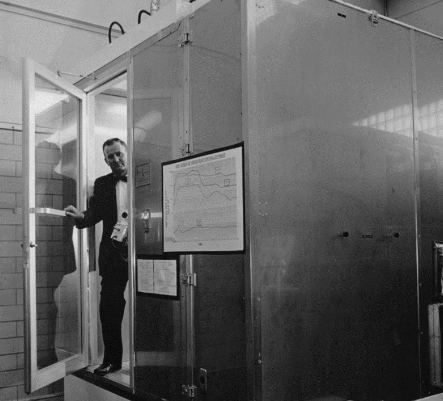

- Entry and Exit Procedures: Clean room personnel are required to follow strict entry and exit procedures to prevent the introduction of contaminants. Entry and exit points are equipped with air showers, which blow particles off of personnel before they enter or exit the clean room.

- Equipment: Clean room equipment is designed to prevent the introduction of contaminants. Equipment is typically made of non-shedding materials, and some equipment is designed to be sterilized to prevent the spread of contaminants.

Minimizing Risks of Contamination

In addition to preventing contamination from entering the controlled environment, clean rooms also take steps to minimize the risks of contamination from within the controlled environment. There are several strategies used to achieve this goal.

- Cleaning Procedures: Clean rooms have strict cleaning procedures to remove particles from the environment. Surfaces are cleaned regularly using specialized cleaning agents, and personnel are required to follow strict cleaning procedures to prevent the spread of contaminants.

- Material Handling Procedures: Clean room personnel follow strict material handling procedures to prevent the spread of contaminants. Materials are typically transferred in sealed containers, and personnel are required to wear gloves and other protective equipment when handling materials.

- Personnel Training: Clean room personnel receive specialized training on clean room procedures and protocols. This training includes proper gowning procedures, cleaning procedures, and material handling procedures.

- Environmental Monitoring: Clean rooms are equipped with specialized monitoring systems to detect the presence of contaminants. Personnel regularly collect air and surface samples to monitor the environment for the presence of particles.

Maintaining clean room practices is a much more complex and in-depth process than people realize. Not only does the clean room have specific and measurable sanitary structural procedures, but a great clean room involves people that know and can execute the best sanitary practices. These rooms are vital for many reasons and for many industries. It is only a matter of time before they become even more advanced than they currently are.